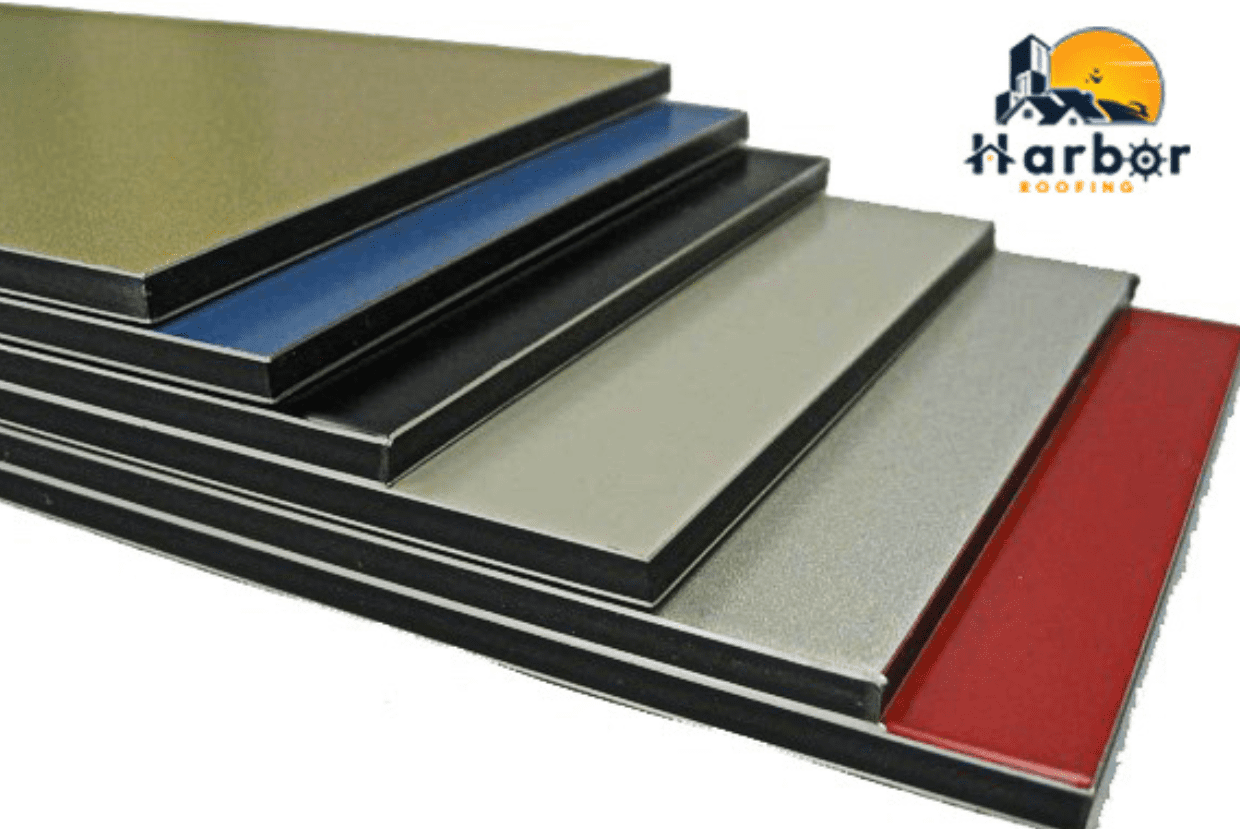

By now, it is common knowledge that metal has become a popular roofing choice. However, it is essential to know that all metal roofs do not have the exact same composition and, as such, should be treated differently. A necessary part of metal roofing that many people tend to underestimate or even overlook is the metal coating system, which is vital to the protection of these metals. Two of the most common systems are PVDF paints and SMP paints.

One common challenge homeowners have is choosing the right paint system for their roof. In this article, we will define each of these systems and discuss their differences, advantages, and disadvantages.

What Is PVDF Paint (KYNAR Paint)?

PVDF (polyvinylidene fluoride) is one of the most used coatings on the market, both commercially and industrially. PVDF is a fluoropolymer with exceptional stability and inertness. It gives metal superior protection from weathering agents over time.

PVDF coatings are a type of coating technology based on resin. When people need long-lasting paint for their projects, they use this coating system for protection against harsh elements that may lead to weathering, fading, and chalking. It also protects their projects from UV radiation. PVDF coatings give exceptional protection to the coated metal and improve its look.

Pros and Cons of PVDF Paint (KYNAR Paint)

Pros

- High resistance to fading: Because of its chemical composition, PVDF can keep its initial color and brightness longer than other paint systems. Using PVDF will give your metal roof protection against hazardous UV rays, therefore preventing fading.

- Durability: It has a really long lifespan compared to other systems. Although the warranty for this system usually covers chalking and fading for a more extended period than that for SMP systems, it differs between manufacturers.

- High chalking resistance: When you leave some painted panels exposed to the sun for a long time, the paint’s pigments and resins start to break down chemically. This process is called chalking, and it results in the formation of a powdery substance. PVDF delays the chalking process compared to a weaker paint system as it is more resistant.

- Availability in different colors: PVDF leaves you with many options to pick from when it comes to colors. The panels are available in a broader selection of finishes, paint prints, and custom colors. You can pick outstanding colors and designs.

- Helps sustain an even color: Many times, when one side of the roof gets more protection than the other, uneven fading occurs. The side exposed to the sun will appear duller than the other side with less exposure. However, PVDF paint helps your roof maintain an even shade.

Cons

- More expensive: PVDF is more costly than other systems. The manufacturers produce them with superior-quality paint resins and heavy metal panels.

- Low abrasion resistance: This paint is easy to scratch because of its soft nature. For this reason, you need extra care in handling them during transport and installation to prevent the panel’s surface from getting scratched.

What is SMP Coating?

When it comes to coatings people frequently use on pre-painted steel, SMP (silicone-modified polyester) coating makes the top picks. Its qualities are a perfect blend of some of the best qualities of polyester and silicon resin. These qualities include good wear resistance, color retention, and exceptional corrosion and weather resistance. Usually, SMP has a lifespan that exceeds ten years.

Due to its attributes, people usually use SMP color coated steel for roofing and wall panels in light industrial, commercial, and residential locations. Steel mills and places that experience heavy sandstorms also use it.

SMP coating has some advantages and disadvantages. The benefits include enhanced resistance to scratches, affordability, and warranty on film adhesion. Some of its cons are fading and chalking. Check here for more.

Comparing PVDF Paint and SMP Paint: Which One Is Better?

In the industry, many people consider PVDF coated panels to be of better quality and performance than SMP panels. This perceived superiority also contributes to the significant difference in cost between the two, as PVDF costs more.

Making a choice between these two panels eventually boils down to concessions between cost and functionality.

Chemical Structure

When making SMP coating, manufacturers use intermediates of silicon and polyester. The silicone in the coating improves its ability to withstand harsh weather conditions and retain its gloss. The quantity of silicone in the coating is different for different manufacturers. The performance gets better as the amount of silicone increases.

On the other hand, PVDF coatings contain the carbon-fluorine bond, which is known to be one of the strongest bonds. PVDF’s chemical makeup allows it to be resistant to strong acids, reducing agents, and solvents.

Abrasion Resistance

SMP paints are more resistant to abrasions and scratches than PVDF paints because SMP has tougher resins than PVDF. However, despite its toughness, SMP is less flexible, which may lead to minor fractures.

Due to PVDF paint’s softness, it can form easily and has a lower risk of fracturing. This same quality of softness makes it easily susceptible to scratches.

Fading and Chalking

Although the silicone in SMP improves its resistance to fading and chalking, the paint still loses some of its lustre to UV rays over time. Specific colors tend to fade more quickly than others, especially red, which is the fastest. With lighter colors, chalking is less conspicuous.

PVDF contains a potent chemical base. Hence, it can endure the harsh elements of the environment and provide protection for a very long time.

Cost

You will find SMP paint systems with improved components but at more costly prices. They are of superior quality and contain ceramic pigments, which increase their fade resistance, and better resins, which reduce the occurrence of chalking.

Usually, PVDF paint can be around 15-35% more costly than SMP. This is due to the fact that PVDF contains components of higher quality.

Paint Warranty

It might come as a surprise to you that SMP panels offer a more extended warranty since many people consider them inferior to PVDF in terms of quality. It is quite expected that you will see a warranty of 40 years when searching for an SMP panel warranty. Anyone would get easily excited to see that, but on closer observation, you’ll discover that this warranty only applies to film adhesion. Usually, the fade, chalk, and color change coverage is not as extensive as the PVDF panel warranty.

For PVDF panels, the guarantee for film adhesion generally lasts 20 to 40 years. In fact, the color change is dependent on the kind of color. For chalking and fading coverage, you may need a guarantee of ten to thirty years.

Conclusion

Generally, when it comes to functionality and quality, PVDF coated panels are perceived to be of a better standard than SMP coated panels in the industry. Despite this knowledge, deciding between these two paint systems can be a challenge, as both have their benefits and shortcomings.

PVDF paint and SMP paint are, without a doubt, great options. However, making the best decision depends on what you are willing to compromise. Just make sure you consider both advantages and disadvantages carefully. It should aid in your decision-making.

Frequently Asked Questions

How long does SMP paint last?

Realistic warranties for SMP paints have reasonable warranties that range between 10-20 years. This warranty usually covers outstanding fade and chalk resistance and gloss retention. However, you’ll also find companies that will give you more extended, unrealistic warranties. Well, if you ever come across one, you should read the warranties carefully to avoid paying for a product that won’t last.

How long does metal roof paint last?

The average lifespan of metal roof paints is between 30 and 40 years, offering prolonged protection and aesthetics. However, vibrant colors tend to have a shorter lifespan and have the potential to last for about ten years. Hence, if you want your roof to retain its aesthetic appeal and functionality for a long time, you should go for paints of high quality.

What is fading and chalking?

Fading is the observable loss of color over time. Chalking, on the other hand, is a powder-like substance that starts to form on a coating’s surface. Fading and chalking happen when the pigments and base resins present in the coating chemically disintegrate. These occurrences are usually a result of exposure to UV light from the sun.

Why is PVDF paint better than other paint systems?

PVDF is a better paint system because of its excellent performance, high resistance to fading and chalking, and strong chemical resistance. Strong resistance to fading and abrasion is necessary for metal roofing since the painted surface is repeatedly subjected to adverse elements like debris and UV rays.