There’s more to a roof than you know. One of the many components that make up a roof is the flashing. However, many are in the dark about it and have no idea why it is essential to their roof’s functionality.

In this article, we will define roof flashing and discuss its types and role in the grand scheme.

What Is a Roof Flashing?

A roof flashing is a metal strip that channels water away from particular areas, like the roof deck and joints on your roof. It is positioned at joints on the roof and functions to prevent roof damage. When used on shingle roofs, they install it between the underlayment and shingles. But on metal roofs, they install it just on top of the panels.

Copper, steel, or aluminum are some of the most common metals manufacturers use in making flashing. However, galvanized steel, which is budget-friendly and long-lasting, tops the list as it is the most used material. For those with enough to spare financially, copper is the ideal material. It is more visually pleasing and durable than steel.

Types of Roof Flashing

Some of the most common types of flashing in the industry are:

- Apron or continuous flashing

- Valley flashing

- Base and counter flashing

- Drip edge flashing

- Wall flashing

Apron or Continuous Flashing

Apron flashing, also known as continuous flashing, is a single metal piece that covers the complete length of the joint it is protecting from water damage. It is commonly used where protrusions or dormers connect with a roof’s surface. The benefit of using flashing like this is that it eliminates the chances of a leak occurring. However, with a constant change in external temperature, a single metal piece can’t expand or contract. This means that, over time, it can snap.

Valley Flashing

Valley flashing serves as a V-shaped passage for water through locations where two roof slopes meet. It requires more precautionary steps as rainwater passing through it happens frequently. You can leave valley flashings to be conspicuous and easy to identify or concealed beneath shingles.

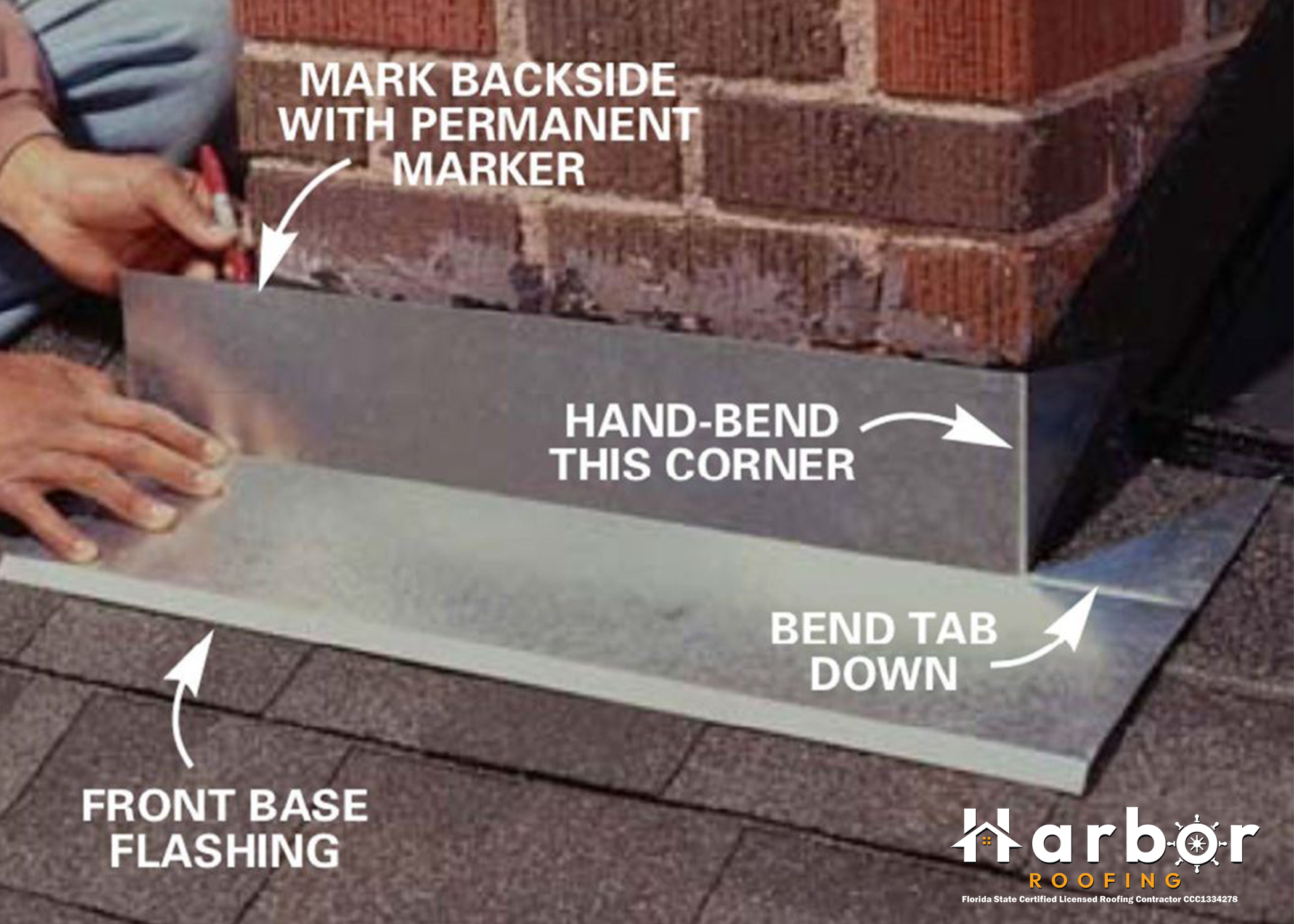

Base and Counter Flashing

Experts combine these flashing types to make up a set to protect features that are challenging to waterproof. An example of such a feature is a chimney. You attach a counter flashing to the roof penetration instead of the roof itself. In contrast, you attach the base flashing to the roof. The base is usually an L-shaped flashing that overlaps with the counter flashing without being attached. The combination of these two gives room for more expansion and contraction without fear of damage.

Drip Edge Flashing

Professional roofers fix this flashing of different shapes to the edge of the roof to hinder rain from trickling down the fascia boards and into the soffits. Drip edge flashings exist in F, T, and L shapes, with L being the simplest.

Wall Flashing

For additional waterproofing, roofing contractors usually install this flashing around the roof-to-outside wall intersection.

Why Is Roof Flashing Important?

Flashings protect the areas on your roof that are prone to leaks, like roof valleys and penetrations, preventing water damage. That function is what makes them essential. Failure to install flashing on areas of your shingles positioned against an open roof valley or chimney will cause a leak. When water gets under your roof or shingles, it leads to deterioration from mold, rot, or mildew.

While sealants work for small gaps, flashings are better for protecting a larger surface area from water leakage. Flashings are vital to your roofing system. They are affordable and are not challenging to install.

Materials Used for Flashing

Roof flashing is typically made of metal, but there are several metal flashing types to choose from. These materials include:

- Galvanized steel: Galvanized steel is the most used material for flashing. It is cheap, resistant to corrosion, and lightweight. These qualities are what make this material a top choice.

- Aluminum: Like galvanized steel, aluminum is lightweight and cheap. However, it is not resistant to corrosion. You have to coat it to avoid corrosion. It is not ideal for beachside homes or masonry.

- Copper: Copper is sturdy, resistant to corrosion, long-lasting, and easy to work with. It is, in fact, an excellent flashing material. The major downside is that it is expensive. However, if you can afford it, it is a perfect choice of material. It will serve you for a very long period without the need for replacement.

- Lead: Lead is malleable, making it an ideal material for flexible flashing. Because of its softness, lead is easily bent, so manufacturers seldom use it for flashing. In addition, it can release toxic discharge when left uncoated.

Flashings also exist in other materials, like synthetic materials. Examples include acrylic and plastic. Although they are not ideal for long-term exposure, their flexibility makes them useful.

Roof Flashing Maintenance

Maintaining your roof is essential. We recommend having a professional inspect your roof at least five years after installation. This practice will ensure that your roof flashing and other parts of your roofing system are not damaged. If there are impending or minor damages, the professional can detect them before they become bigger problems.

Additionally, your flashing needs maintenance to ensure it is still functional and the material is in good condition. You might be tempted to brush it off as insignificant, but don’t fall for that temptation. Routine flashing maintenance will save you money that you would have spent on expensive repairs or replacements.

When Do You Replace Your Roof Flashing?

When you start to observe the following signs on your roof or flashing, you know you are due for a replacement.

- Rust marks or cracks on your flashing

- Sagging of roof or roof rot

- Leaks in areas surrounding the roof valleys and penetrations like chimneys

- Asphalt shingle age is beyond 20 or 25 years.

Conclusion

We can’t overstress the essence of a roof flashing; hence, we advise you never to underestimate its value and to pay attention to its maintenance. A roof flashing is a single metal strip that protects your roof joints and prevents water damage and leaks. It is affordable and easy to install.

Now that you are better informed about flashings, their types, importance, and maintenance, you should include one in your roofing system. Additionally, you should carefully care for flashings and invest in ones made of non-corrosive materials. We also recommend using a licensed expert to inspect the roof when necessary.

Frequently Asked Questions

What happens if you don’t have roof flashing?

When you don’t have a flashing or have one that is damaged, what happens is that you expose your roof to the risk of having leaks in your roof. Leaks can cause great damage to your roofing system and home, especially when you do not notice or fix them early.

What is the purpose of roof flashing?

The purpose of roof flashing is to protect your roof and home from water damage. Many roofs have wooden bases. Prolonged exposure to water can easily damage wood, shortening your roof’s lifespan. When your roof has a flashing, it protects it by directing the water flow away from the roof.

Can you install flashings on roofs with skylights?

Absolutely! Although installing one might be challenging, it isn’t something a professional cannot handle. Even when the skylight fits the opening perfectly, the area will still be susceptible to leaks. Hence, flashing is necessary. Many skylights have a frame that accommodates the installation of flashing around the edges.