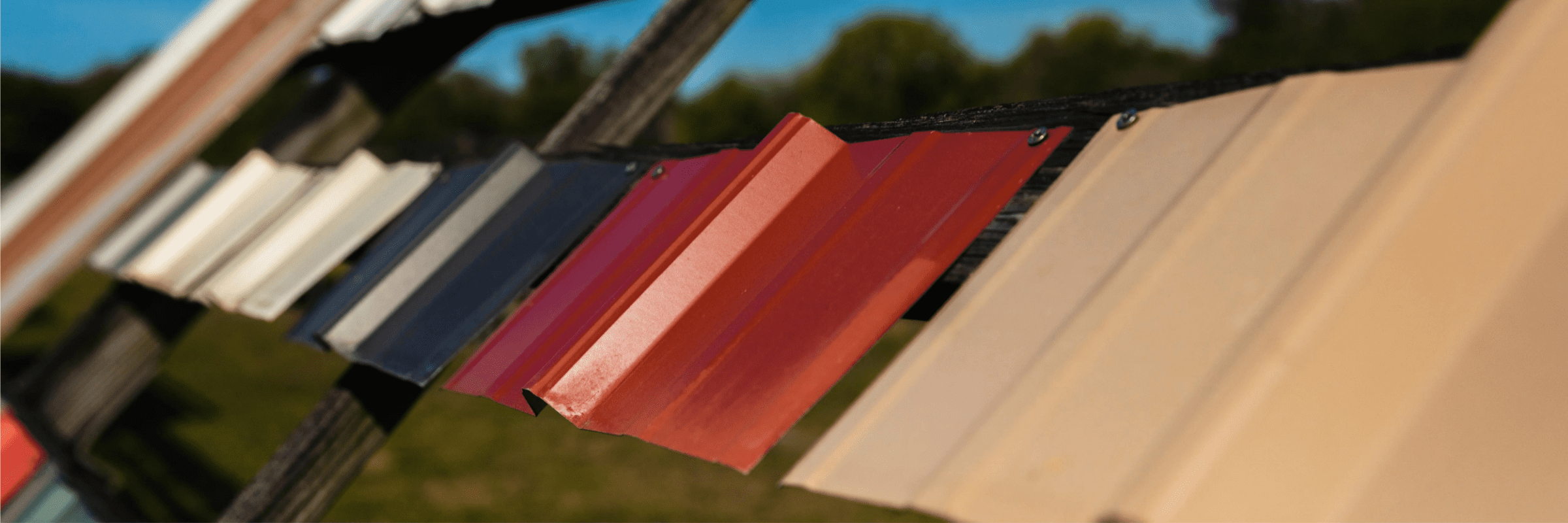

When people make a decision to coat their metal panels, they usually go for either polyester, silicone-modified polyester (SMP), or PVDF (Kynar 500). PVDF finishes are the best at protecting against fade and chalk and have also been shown to last the longest.

PVDF resin-based coatings have the reputation of being durable. They protect for a long time. They give homes and business owners beautiful, long-lasting roofs that do not lose their curb charm year after year.

People in the metal roofing industry sometimes call PVDF Kynar 500® or Hylar 5000® in the metal roofing industry. These are just brand names for products that use the same formula for PVDF resin.

Brief History of Kynar 500

In 1948, DuPont Corporation created polyvinyl fluoride film and got a patent for it. Pennwalt Chemicals bought the rights and created the licensing program that made it possible for people to use the colored liquid covering on a large scale in commerce.

Once upon a time, this finish was sold under the brand name Kynar 500. Elf Atochem, now called Arkema, bought Pennwalt in the 1980s. The Federal Trade Commission told Elf to sell one of its factories. Ausimont, USA, now Solvay Solexis and the second-largest producer of PVDF coatings (under the brand name Hylar® 5000), bought it.

Polyvinylidene fluoride is now considered by many to be the best plastic for sealing metal on the outside.

Why Kynar 500 Coating Matters

When choosing the kind of coating you put on metal panels and roofs, you have to be very intentional about it. Nature can attack at any time, and buildings must be able to resist hailstorms, nuts flying through the air and hitting the house in a gale, and other unplanned disasters. In addition to being able to handle impacts, paint also needs to be able to resist tarnish and rusting caused by acid rain and salt air at the beach.

You must have witnessed horrible situations of paint peeling and fading in real life. Vehicles often experience this for a variety of reasons. Fortunately, Kynar-coated products don’t have the problem of peeling and fading.

In order to keep their paints working well for many years, Kynar’s makers have been making trade-protected metal-painting mixtures backed by solid guarantees for more than 50 years.

The Science Behind It

Did you know that, individually, the six Kynar 500 coats play different roles in shielding metal panels? Well, steel usually receives galvanizing treatment, which acts as the first or initial coat on naked steel. 100% zinc makes up this film that makes steel products last more than 50 years. Even when you leave the treated metal exposed to water for a long time, the film doesn’t give way. You know why? It’s because galvanizing does a great job of protecting metals from rust.

It gets more interesting to know that manufacturers use more than galvanizing for Kynar products. They use the unique Galvalume method for some panels. Because it’s made of copper and aluminum, it’s even stronger. When put on, the mix of 45% zinc and 55% aluminum doesn’t look like galvanized finishes because the crystals are smaller and more packed together, making the finish smoother. The most important thing is that, even decades later, it’s often better than standard galvanizing at keeping water and rust away.

Further Breakdown of the Science

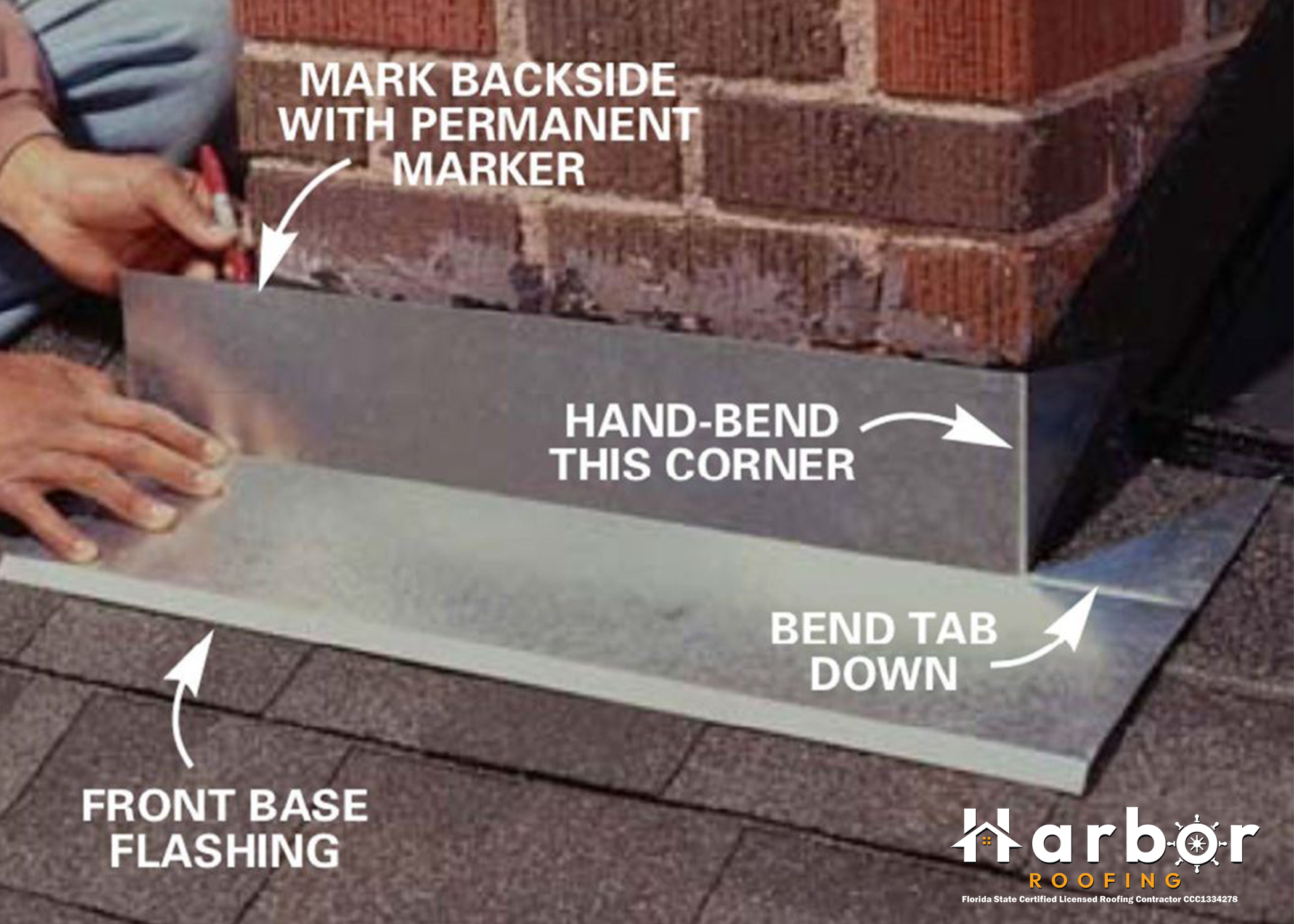

The layer of protection the coating expert uses is either galvalume or galvanized. It depends on the metal panels or parts you are treating.

Painters use a special method for Galvanizing or galvalumeing the coat. This method is “hot-dipping.” It takes more than one step to apply the coat on the steel.

First, they use a solvent to clean the steel. Next, they “pickle” it by putting it in a vat of diluted hot sulfuric acid. Pickling removes impurities like rust and scale, which is a lot like putting steel back in its original state. The next step is to flux the metal because water in the air easily damages iron in steel, which can still rust. This is another chemical cleaning method that stops rust. It is best you do it before joining metals.

The next step is to dip the fluxed metal into a pot of liquid alloy or zinc coating. This makes the galvanizing or galvalume layer.

This zinc-based coat is very important. As the first line of defense, it keeps steel safe. After many years, when the topcoats wear off, and rusting starts, it will begin on the zinc, not the steel, because zinc is the first metal that rust will hit.

Why Do You Need Kynar 500?

Metal must have a finish that adds color and doesn’t dull for functionality and aesthetics. One that won’t lose its shine and color and won’t chip, pit, or age too quickly.

A covering system made from Kynar 500 resins is the only one that can stand up to the elements and the test of time. With its remarkable ability to keep color and gloss, this high-performance fluoropolymer plastic makes the painted metal look bright and appealing.

Kynar is a better option than other thermoplastics, like Delrin, because it can handle high temperatures and doesn’t react with chemicals. Kynar is the ideal choice for you if you want to protect metal from chemicals and UV light for a long time.

When it comes to buildings, Kynar leaves you with a lot of options. You can use it in different ways, such as to protect the roof or walls from the weather. It is so durable that it will keep your metal in great shape for a long time.

Properties of Kynar

By now, after seeing the definition of Kynar 500 and why you need it, you must already know that it has numerous properties that are beneficial. Now, let’s get into these properties:

- Relative thermal index (RTI) rating: Kynar 500 has an RTI rating of 150 ºC. This means that until it reaches 150 ºC, it won’t lose its characteristics or depreciate in quality.

- Resistance to radiation: Its structure, qualities, and tensile strength can handle electromagnetic radiation up to 100 Mrads.

- Resistance to sunlight/UV: This property shields the product from deterioration caused by the sun.

- Resistance to chemicals: You can rest assured that the chemicals in your household or environment won’t diminish your Kynar coating.

- Adaptable and easy to use: You can easily use it for your house renovation, commercial buildings, and architectural work.

- High resistance to dings: Repairs and commercial work won’t affect the covering or the metal underneath.

- Electrochemical stability: It is electrochemically stable, meaning it can handle both positive and negative electrical currents of many wattages.

- High purity level: It contains strong chemicals.

Pros and Cons of Kynar 500

Pros

- Long-lasting: It’s usually retains colors for a long time, especially very dark ones. Lighter colors also don’t fade quickly.

- Easy to remove pollutants: If you put Kynar on your metal, washing off dirt and other contaminants will be easy when it rains.

Cons

- Expensive: Regarding metal roofs, Kynar 500 is an investment-grade choice because it costs more. The initial investment is on the high side, but over time, the money you’ll save on paint jobs, cleaning, and replacements will be worth it.

- Non-stick nature: It is non-stick; hence, sticking anything to your metal roofing sheets will be futile. Adhesives don’t stick to Kynar® any better than they stick to any other material, so they’re useless.

Conclusion

The kind of coating you use on your metal panels and roofs is very essential. That is why you need to put a lot of thought into making a choice. You need paint that can withstand harsh conditions and resist rust or tarnish. What’s a better choice than the Kynar 500, after all that you now know about it?

Frequently Asked Questions

Is Kynar 500 a tough plastic?

People call Kynar a tough plastic because it lasts a long time, doesn’t react to radiation, is highly resistant to wear and tear, doesn’t crack under stress, and is strong mechanically.

What is a Kynar 500 finish?

It is a paint system that people usually use on aluminum. Galvume, or galvanized steel. It typically has a chalk and fade warranty; many people acknowledge it as a superior quality finish.

What is the difference between PVDF and Kynar?

Polyvinylidene fluoride (PVDF) is a pure industrial substance that is highly resistant to chemicals, wear, fire, and UV light. It is usually sold under the brand name Kynar. People often use PVDF to seal liquid tanks and make parts for semiconductor equipment.

How long does Kynar last?

The coating expert applies Kynar to the metal panels via a patented process. It has a paint warranty of 30 years. The best part of this paint is that it lasts for as long as 50 years. This is why standing seam metal roofs last 50 years.

Can Kynar be applied to steel?

Yes, it can. You could go around the world, and every architect will recommend Kynar 500® PVDF resin-based coatings to shield your galvanized steel, aluminum, and aluminized steel. No other coating systems can endure the severities of nature and the test of time like Kynar 500 resin-based systems.