Purlins, the horizontal bars or beams that support building structures, particularly the roofing system, are not just a choice but a necessity. Whether they draw support from the building’s walls or rafters, purlins play a vital role. While they are commonly found in metal buildings, they also serve as replacements for closely packed rafters in wood frame structures.

Purlins, with their robust design and reliable support, are crucial for constructing long-lasting buildings. In this article, we will delve into their roles, types, and importance. If you’re searching for a roofing system you can trust to endure the test of time, you need to continue reading to discover how purlins can be your dependable solution.

What Are Purlins?

Purlins are horizontal bars or beams that hold the roof deck, usually a plyboard, wooden panel, or sheet metal. The roof deck makes the roof surface and is generally loaded with weatherproofing of some kind.

Purlins usually receive support from building walls, rafters, or steel beams. They transfer the roof’s loads to the main structural components, giving the roof support. In pre-engineered metal construction systems, professionals usually adopt purlins.

The design factor for the form purlins and their arrangement depend on the limiting sheeting lengths and the kind of roof loads. This is why people should become familiar with the local building codes and apply them to the design of the concrete roof structure.

There is a wide array of purlins, each unique in its material and shape, catering to various structural needs. From providing support to structural walls or floors to being an integral part of the roof structure, purlins are indispensable. Without them, there would be no frame for the sheeting on the roof to rest on, emphasizing their importance in the overall roof structure.

People use steel purlins instead of traditional wood purlins. They are lightweight, simple, precise, and have fixed measurements. Manufacturers can make steel purlins from either cold or hot-formed steel. However, manufacturers typically produce steel purlin with cold-formed steel, which is thin enough to pass through screws, because it is cheaper and easier to deal with.

Manufacturers of cold-formed steel transform it into the preferred shape by pressing or rolling thin sheets of steel. Cold-formed steel, despite being more robust than hot-formed steel, has a higher chance of cracking than bending when it is under tension.

Manufacturers make purlins with different metals; some have zinc coatings of varying GSM, while others are basic mild steel.

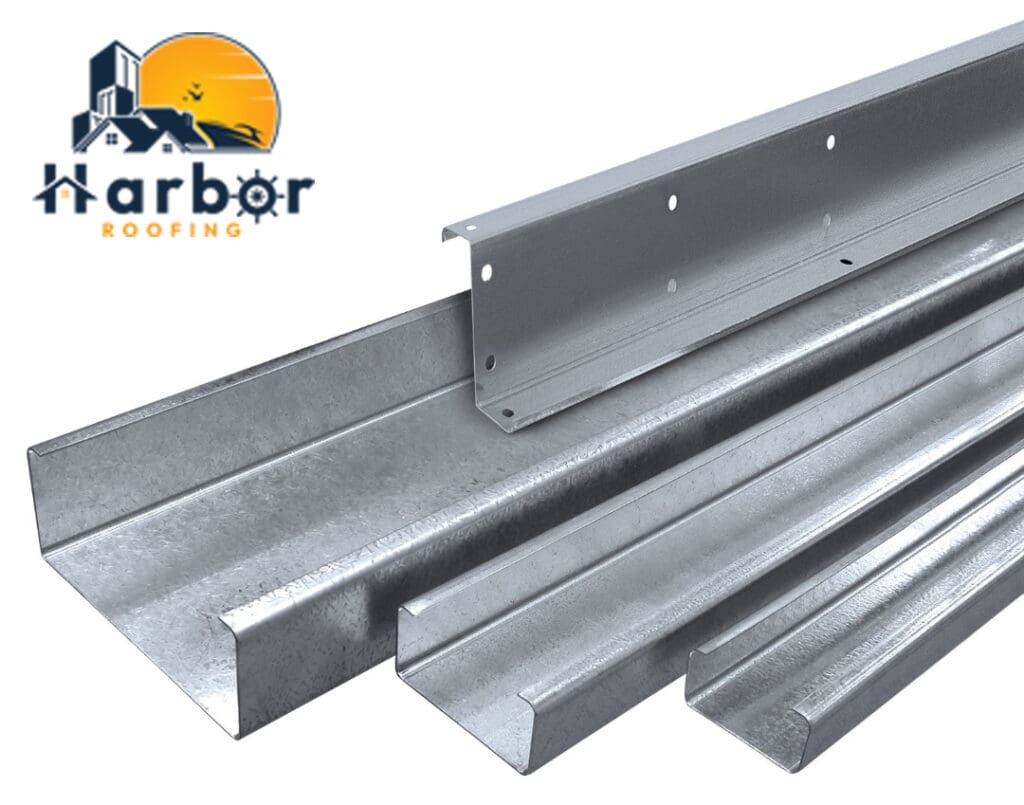

Types of Steel Purlins

C Purlin

C purlin, like its name, is designed to form a C shape. People also call it Cee section purlin or C section purling. Professionals mainly use C purlins to support floors and walls. Their design makes them ideal for supporting the beams needed for flooring.

Advantages of C Purlins

- It is sturdy

- Guaranteed alignment

- Has the capacity to cover a distance

- Side drilling is not necessary

- It does not need cutting

Z Purlin

Z purlins are z-shaped purlins commonly used at overlaps and joints. They are horizontal beams designed to give form to a building’s shell structure’s wall joists and roof. Z purlins (Zed purlins) act as a sheet aid between the building and roofing sheets to ensure that the sheets are fixed firmly and held in place.

This purlin type is lightweight and highly flexible. These properties make them popular for use in industrial and agricultural buildings. The Z purlin shape aids in overlaying the joints, making them stronger and more durable than C purlins. Their strength makes them perfect for large structures.

Advantages of Z Purlins

- Stronger than C purlins

- Reduces purlins’ height and, therefore, saves materials

- You can overlap them

Spacing for Roof Purlins

It is important to consider the spacing for metal purlins before erecting the system. The rule of thumb is that the heavier and bigger a metal roofing structure is, the greater the space you need to leave between the principal rafters and purlins.

In most structures, the standard spacing is between 12″ and 24.” However, this standard has some exceptions due to the customers’ requirements. Many manufacturers of metal roof purlins and building regulations advise that:

- When supporting secondary framing and steel framing, you shouldn’t space the purlins apart beyond 30 inches. When supporting sheathing, they should be 38 inches apart.

- Engineers and contractors should use excellent judgment when spacing metal roofing purlins during constructions that have a light frame for lengthy spans.

When spacing your purlins, you can consider the following tips:

The center-to-center spacing should not exceed 30 inches if there are over five purlins in a span. You can utilize more purlins in a situation like that.

Design the purlins in pairs in a situation where the roof span is greater than 50 feet, with a higher purlin at the center supporting two lower spans spaced 30 inches away from each other.

Place one end post for each lengthy span. The end post must be at least 200 feet long and have a bearing plate installed to give the purlins support.

Size of Roof Purlins

Manufacturers produce purlins in different sizes, known as gauges. The two types of purlins, C purlins, and Z purlins, are available in three different sizes: 16 gauge, 14 gauge, and 12 gauge. You may have to consult an expert to determine the most suitable size for your building project.

Importance of Roof Purlins

We can’t overlook the importance of purlins in metal roofing construction. They are fundamental, as they give the walls and metal roofing sheets support and keep them from falling apart. Purlins are necessary to hold your building structure together and prevent it from collapsing. They have what it takes to support insulation, cladding, and roofing sheets inserted into steel beams.

Purlins are versatile and multi-purpose, in addition to being an important part of roofing construction. You can apply them to wall support, flooring, and aesthetic finishes on door frames and window trimmings. An example is the application of purlins for the construction of mezzanine flooring to include more space without performing any severe construction work.

Conclusion

Purlins have a strong design and reliable support and are essential for assembling durable buildings. They play a vital role in ensuring the metal building is rigid and firm. If you are planning to get yourself purlins for your building projects, we advise that you speak with a construction engineer for guidance.

Frequently Asked Questions

What is the purpose of the under purlin?

In a traditional roof frame, the underpurlins support the rafter’s underside. This prevents the roof from drooping and collapsing while giving room for the most economical rafter size. When feasible, the underpurlins should be of a single length. You have to position them at a straight angle to the direction of the rafters in straight runs.

Where should purlins be placed?

The purlins typically run parallel to one another along the roof’s whole length, and they are spaced at regular intervals. That way, they can support the weight of the roof covering. Therefore, as soon as you install the purlins properly, you can place metal sheets or roof tiles on them.

What is the cost of metal roof purlins?

The size, thickness, and location of the project’s site all impact the cost of metal purlins, which varies. For example, heavy gauge purlins cost more than less dense metal purlins. Manufacturers use steel more in deeper purlins than in shallower ones. Hence, a 10′′ deep purlin costs twice as much as a 4′′ deep purlin.

What is the difference between rafters and purlins?

Rafters are wood beams inclined upward from the ground. They assemble at the top of the ridge beam gable and are fixed to the rafters with additional bracing. On the other hand, the purlins are the wide beams that run perpendicular to the rafters.

How do you support roof purlins?

You can support purlins by locking them all in place and fastening them to other sturdy roof components. Usually, the best thing to do is to fasten the purlins to the roof’s rafters. A rafter is the roof’s frame that runs the length of the building.

What are the maintenance tips for purlin?

To prevent severe damage from occurring to your purlins, you need to give them equal support from both ends. It is best to inspect the purlins for deterioration regularly. We also recommend that you clean or galvanize your purlins regularly to reduce the chances of rust happening.