Below is a list of 5 very common ways roofers cut corners to save time and money. Many of these poor roof installation practices are easy to get away with while still passing all of the required inspections. These corner-cutting techniques are hard to verify, and most of them don’t technically violate any building code requirements. Nevertheless, these practices should be avoided at all costs, even if it means paying a little more for your new roof.

1. NOT POPPING CHALK LINES

Us roofers commonly hear other roofers brag about how they can keep their shingle courses straight without popping a single chalk line. The fact is, every roofer no matter how experience should never skip this popping chalk lines. Popping chalk lines ensures your shingle courses are as straight as possible across the entire roof. No building is built exactly square; and not matter how good a roofer’s eye is, he isn’t going to be able to account for that when laying shingles without chalk lines.

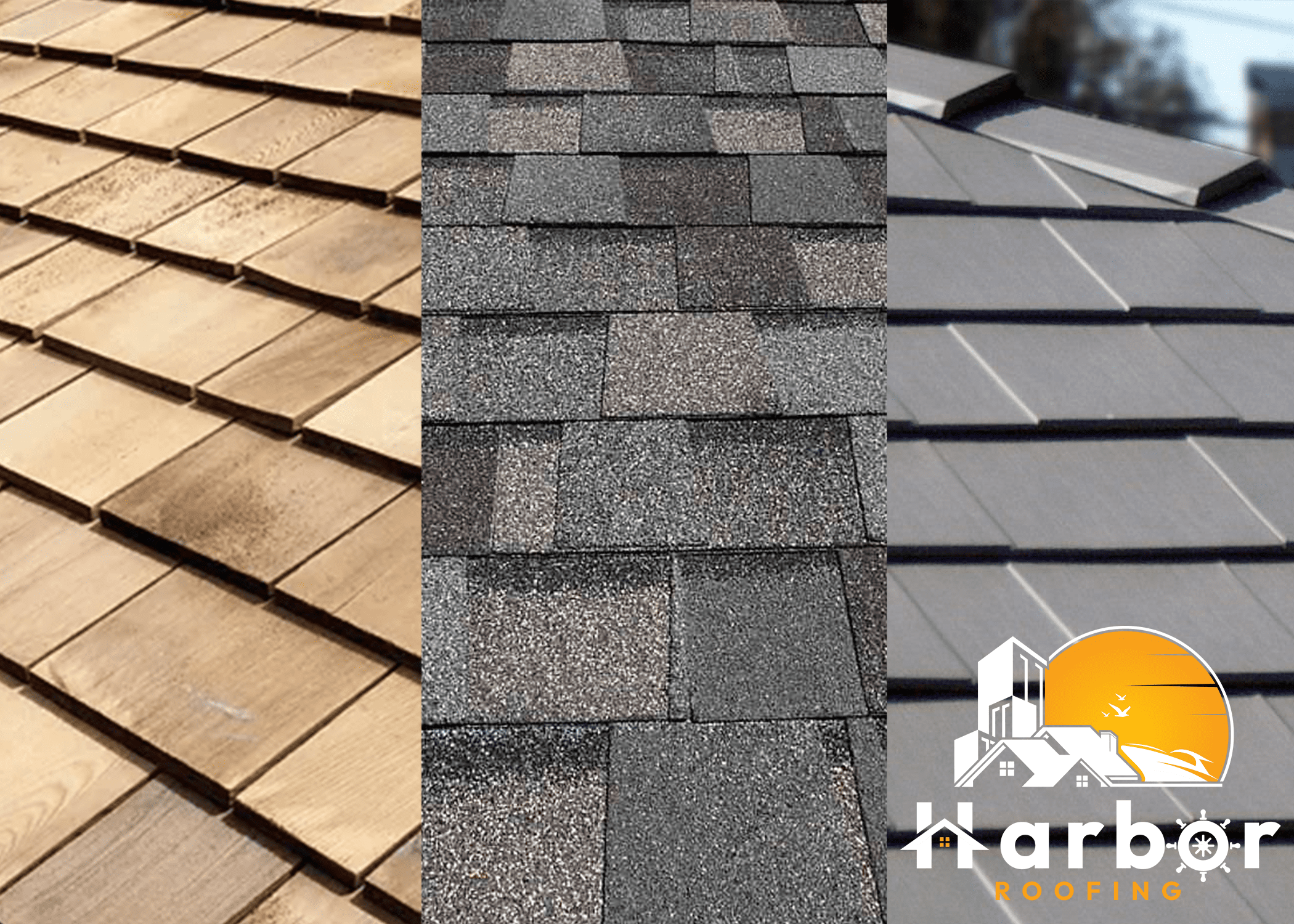

2. CUTTING 3-TAB SHINGLES FOR THE HIP SHINGLES

Cutting similar colored 3-tab shingles to use as hip shingles on a hip roof was a common practices back in the day that is still used by many roofers in Florida. But as you can see in the picture, the hip shingles never match perfectly. Shingle manufacturers such as GAF make hip shingles such as the TIMBERTEX designed to match the shingles in the fields. These hip shingles come from the same manufacturer plant and use the exact same mix of granules. Roofers can save money by using 3-tab shingles, but the result isn’t worth the money they saved.

3. USING SHINGLES MADE FROM A DIFFERENT MANUFACTURER PLANT

Two different bundles of shingles can be the same color, made by the same manufacturer. But if they weren’t produced from the same batch of granules from the same manufacturing plant, they still won’t match in color. This results in a roof that has mismatched color patches throughout the roof. The most common reasons this happens is either the roofer has used leftover shingles from another job to save money, or the roofer didn’t order enough shingles in the initial order and had to purchase more shingles that were produced in a different batch that the shingles from the original order.

4. Rushing the Underlayment Installation and/or Using the Wrong Underlayment for the Weather Conditions

In Florida it gets extremely hot; especially on the roof. In hot Florida weather, some peel-and-stick brands are extremely difficult to work with as they tend to melt to the roof before the roofers can even enure the rolls are rolled out straight & flat. Then as the roofers are walking on the peel-n-stick underlayment, it slides down the roof causing even more bubbles and fishmouths. THESE FISHMOUTHS & BUBBLES WILL ABSOLUTELY SHOW THROUGH THE SHINGLES. The only way to ensure this doesn’t happen is by either backnailing the peel-n-stick underlayment ensuring it stays put, and/or installing a peel-n-stick underlayment that is better suited for hot weather applications. The Peel-and-Stick we like to use for hot weather application is made by Resisto.

5. NOT RE-NAILING THE DECK AFTER TEAROFF

Yes, renailing the deck is time consuming and costly; but re-nailing the deck during a roof installation should never, ever be skipped. The roofing codes have changed in Florida, and if your home was built before 2005, there is a good chance the way your deck was nailed to the trusses or rafters does not meet the current Florida Building Code requirements. A lot of the old plywood may be warped and delaminated. Warped, rotten, and delaminated plywood should always be changed out and nailed with 2-3/8″ 8(D) ring shank nails spaced 6 inches apart.