Galvalume is one term that tends to confuse many who aren’t well-versed in roofing terminologies. It is a type of metal that is in high demand because of its functionality and several benefits. However, as we said earlier, people sometimes confuse Galvalume metal with galvanized steel.

Before you choose a metal roof for your building, it is essential to know what makes each metal stand out—in this case, Galvalume—and its drawbacks. Knowing their properties and differences will help determine which suits your project better.

In this article, we’ll clear any confusion you may have by describing Galvalume and discussing its applications, limitations, and benefits.

What Is Galvalume Metal?

Galvalume is a kind of steel metal, and its invention came about in the 1970s. It comprises steel, zinc, and aluminum, three of the most relevant metals in the roofing industry. Manufacturers produce it at a high temperature of 600°C by hot-dipping a carbon steel base sheet continuously with zinc and aluminum alloy until it is 55% aluminum, 43.4% zinc, 1.6% silicone, and some trace elements. The combination of aluminum’s increased durability and protection and zinc’s electrochemical protection, among other outstanding properties, makes this metal type a popular choice.

Applications of Galvalume Metal

Generally, you can use Galvalume for roofs, trims, walls, and other applications. However, one of its most prevalent applications is outdoor metal paneling and roofing due to its high corrosion resistance. It is commonly used in the following:

- Home appliances: Galvalume is used in home appliances such as air conditioners, solar water heaters, and refrigerator back panels.

- Automobile industry: In the automobile industry, manufacturers employ Galvalume metal to make exhaust pipes, fuel tanks, mufflers, car body panels, and other parts.

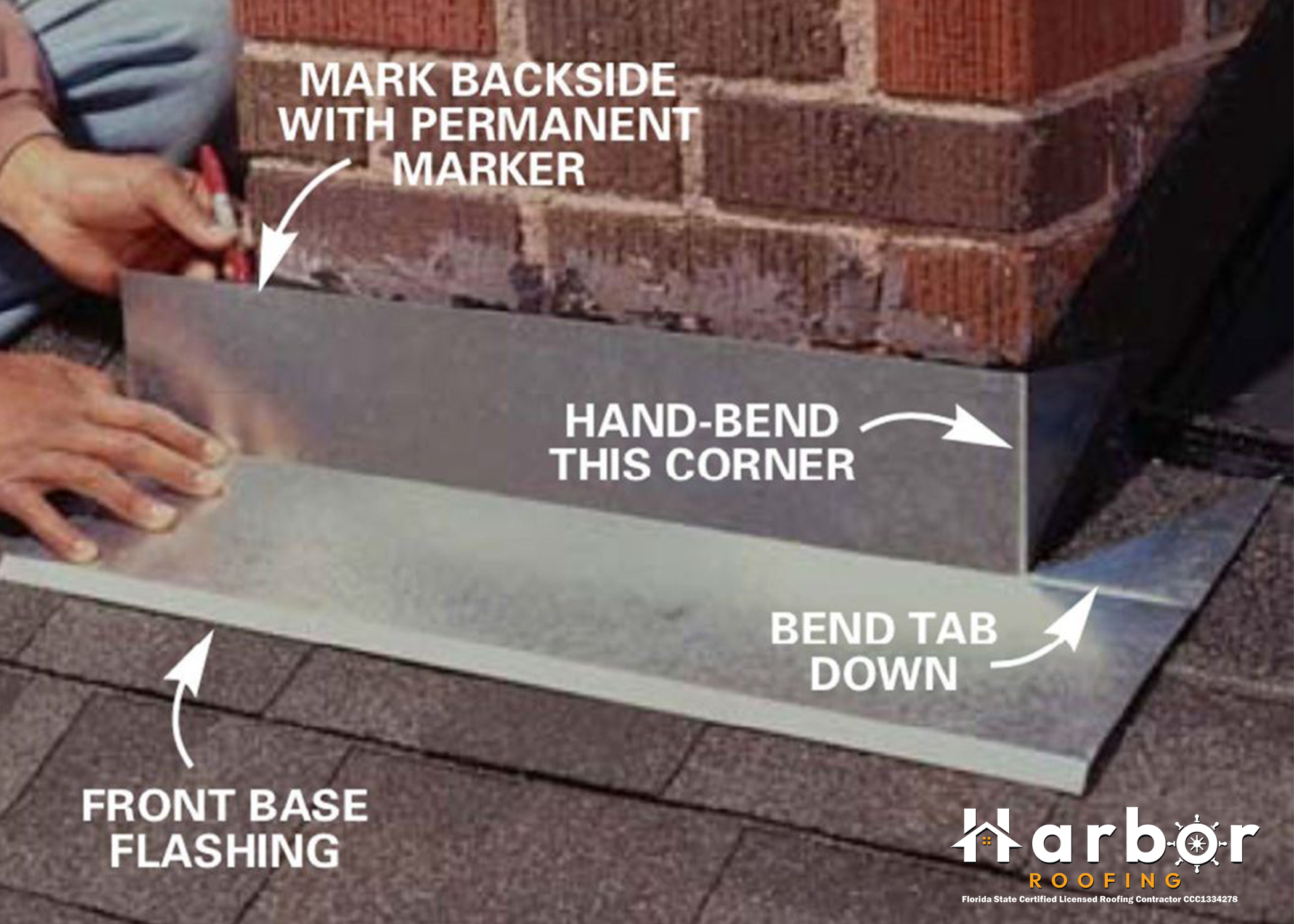

- Construction industry: This steel type is used for roofing panels, fence panels, door panels, partition walls, garage doors, and chimneys.

- Industrial uses: Some industrial uses include electric control cabinets, vending machines, and industrial freezers.

As much as this metal type is in high demand, there are some cases where it is not suitable for use because the coating may disintegrate early and cause a failure in the system. Some of such cases include:

- Coastal environments: Galvalume’s coating can’t withstand coastal conditions. When sodium chloride (salt) comes into contact with Galvalume in large amounts, it destroys its coating and disintegrates the wall or roof system. This will, in turn, shorten its lifespan. That is why experts recommend that individuals with properties in proximity to the coast use an engineered aluminum roof system. Aluminum is a better metal option for coastal areas because it can withstand saltwater for a much longer period without corroding.

- Animal sheds/shelters: Using Galvalume metal on animal shelters is not advisable. When animals pass out waste, the waste disintegrates after some time into ammonia gas, which starts a reaction with the Galvalume coating. This reaction causes the coating to break down, and when this happens, the metal degradation occurs.

Although experts do not recommend this metal type for buildings housing animals, some farmers use it on contemporary chicken shelters that they build with a vapor barrier. The vapor barrier is usually between the roof and the chicken area for sufficient ventilation.

Advantages of Galvalume Metal

- Superior corrosion resistance: Galvalume’s resistance to corrosion is two to four times that of galvanized steel. This is due to the combination of the best qualities of zinc and aluminum, which offers double protection. When zinc fades, the aluminum will create a thick aluminum oxide layer, which will contain further corrosion of the base metal. According to research, Galvalume metal roofing can stay up to 50 years and more without being corroded.

- Aesthetically pleasing: Galvalume has a silver-white color with a smooth surface that gives it a visual appeal. Unlike galvanized steel, it has more uniform spangles. It is a significant reason why more people prefer to use it for their buildings.

- Warranty on substrate: Galvalume’s 25.5-year substrate warranty is a significant advantage. Some people refer to it as the perforation warranty. In addition to the warranty on the substrate, Galvalume systems usually have paint warranties, protecting your investment even more and extending its lifespan.

- Heat resistance and reflectivity: This type of steel has good heat resistance and can endure temperatures as high as 315°C for a lengthy period without losing or changing its color. In addition, it has a heat reflectivity that is two times that of galvanized steel. These properties make it the ideal choice for roofing.

- Good adhesion: Galvalume doesn’t need weathering or pretreatment before you can paint it directly. Because of its good adhesion, you can paint it directly. It is commonly used for color-coated steel as the base metal.

Disadvantages of Galvalume Metal

- High cost: Galvalume’s high cost is a major disadvantage. It is a more expensive roofing material than galvanized steel. The use of high-quality materials and the technical coating process are factors in this cost difference. So, this metal is not for property owners on a budget.

- Weak protection against acidic environments: Although Galvalume does well in most conditions, it has a low tolerance for acidic ones. Exposing it to compounds like industrial emissions or acidic rain will only hasten the process of corrosion, causing the coating to wear off quickly. Therefore, it is not an ideal selection for areas with high acid concentrations.

- Lack of color variety: Although some people find Galvalume metal aesthetically pleasing, its lack of color variety puts it at a disadvantage. Unlike roofing materials like clay tiles and asphalt shingles, it usually comes in a limited spectrum of colors. This limitation makes deciding on a Galvalume roof tough for people who prefer specific colors for their roofs.

- Fast deterioration: When one point on a galvalume steel roof corrodes, it only takes a short time to spread to other parts of the roof until the whole roof is affected. This isn’t the same for galvanized roofs. When a part of a galvanized roof corrodes, it doesn’t spread out.

Conclusion

Galvalume steel metal is quite the “celebrity” in the roofing industry. It has several benefits, including high resistance to corrosion, warranty, and good adhesion. Like other metals, it has its downsides, too. Your priorities, budget, and environment will determine if this metal type is a good choice for you. We also suggest that you seek a professional roofing contractor’s guidance.

Frequently Asked Questions

What is the difference between Galvalume and galvanized metal?

The significant difference between them is the coating composition. Galvalume has an aluminum-zinc alloy that consists of 43.4% zinc, 55% aluminum, and 1.6% silicone, while galvanized steel has a zinc coating.

What does Galvalume look like?

Galvalume is silver-white and has an appearance that looks matte. It has consistent spangles but is not as lustrous as galvanized steel. However, many people use it without painting it.

Is Galvalume more expensive than galvanized steel?

Yes, it is more expensive, but not by much. Many factors, including the aluminum-zinc alloy, the manufacturing process, and the coating thickness, put Galvalume on the higher end of the cost spectrum.

Can you paint Galvalume metal?

Absolutely! It has good adhesion, which makes it easy to paint. Although people tend to use it in its natural state, there are exceptions who paint theirs to match their desired aesthetics. So, yes, you can paint yours any color you want.

Is Galvalume metal a good roofing material?

It is undoubtedly an excellent roofing material and a very popular choice among property owners. It has several benefits, including, but not limited to, high resistance to corrosion, high heat resistance, good adhesion, and nice curb appeal.

Is Galvalume stronger than aluminum?

Yes, it is stronger than aluminum. Aluminum is a naturally soft metal and can’t withstand harsh weather conditions like high winds and storms. Aside from being stronger, it is also more economical.